Overview

Industry 4.0, referred to as the next industrial revolution, is becoming the source of new initiatives in automation and digitalization. The journey towards smarter factories and smarter services inspired by Industry 4.0 goals is creating new challenges for workers. They are increasingly operating more and more complex workflows on machines that are often connected, striving towards higher customizations and lower defect rates. In order to achieve this, these workers need to be empowered with a newer set of tools and technologies so that they can become a Connected Worker 4.0. Reality technologies represented via Assisted Reality, Augmented Reality and Virtual Reality have increasingly become an important tool for Connected Worker 4.0.

Introduction to Assisted Reality

Assisted Reality (AR) solutions project contextual information in the worker's field of vision using a wearable device such as Smart Glass. It helps the worker operate hands-free, fetch contextual information and take instant assistance from experts with minimum interference to their field of view. This increases worker productivity and accuracy making the worker connected in the true sense.

For the manufacturing industry, Assisted Reality can be used in the area of assembly, maintenance, inspections, quality checks and material handling (logistics).

AR applications running on wearable devices such as Smart Glass help workers become hands-free from any device. For instance, a technician working on an industrial machine can utilize both his hands while simultaneously accessing the work instructions digitally or talking to a remote expert with the help of Assisted Reality application running on the smart glass that he is wearing.

Implementing Assisted Reality using RTF

Adoption of new and transformative technologies is often challenging for users and organizations. But they still accept these challenges because these technologies can fast forward future business benefits to present, giving successful organizations a significant advantage over the competition. For example, many organizations are implementing workflow and instruction management for their workers using mobile based technologies. We are observing that organizations which are fast forwarding the implementation of the same workflows on Assisted Reality driven Smart Glass are realizing higher workforce productivity improvements.

Breakthrough projects driven by new technologies can provide large business benefit, but they also have high failure risks. These business benefits and failure risks can be managed by following best practices on use case selection, workforce inclusiveness, short feedback cycles and an adaptive framework to deliver innovation.

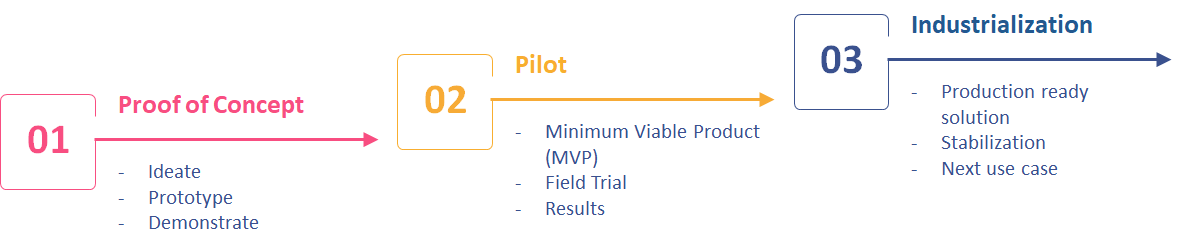

Our Reality Technology Framework (RTF) is a 3 phased approach (see figure 1) that progresses from proof-of-concept to industrialization. It encourages phase-wise development to achieve non-linear milestones and encourages agility in delivering innovation.

Figure 1: Reality Technology Framework for the adoption of new and transformative technologies such as Assisted Reality

How does RTF help?

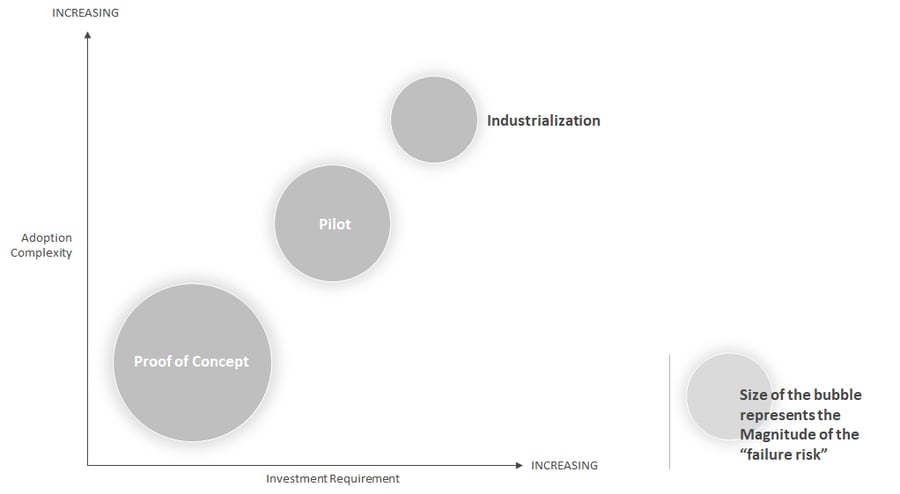

In this framework with each progressive phase the scope of work increases and hence the investment required also increases. In the early phase, wherein a proof of concept is built the risk of failure is the highest because multiple factors may influence the outcome. Hence, it is important that the investment is calibrated carefully across different phases to avoid escalation of commitment.

Figure 2: Benefit of RTF – Risk management

The ‘Proof of Concept’ phase focuses on identification of most promising and feasible use cases and then creating quick prototypes to evaluate the benefits. The investment required for this phase should be low and only a few select features should be built into the prototype to ensure low complexity of adoption. This phase should however address the largest risks, especially those risks which in future can lead to project failure. The top three risks which should be considered are:

- Selecting the right use case

- Obtaining senior management support/leadership buy-in

- Considering the right user experience while creating and evaluating the prototype

Phase 2 i.e. the ‘Pilot’ phase is designed to create a minimum viable product (MVP) based on the selected use cases in phase 1. This should be done by expanding the scope from proof-of-concept and also key users should be involved. This MVP is then tested in the field for validating the benefits, getting end-user feedback and presenting the results to management for further adjustments or scaling up the MVP. This phase would typically require low-to-medium investment to develop a live, but limited, system. The adoption complexity of this phase is typically medium because the MVP is used by (limited number of) end-users in the field. Since major risks were addressed in phase 1, the failure risk becomes lower in phase 2. The top 3 risks which should be addressed in this phase are:

- Technology feasibility

- End-user buy-in for the new system and new/augmented processes

- Demonstrating the value generated to key stakeholders

Once phase 1 and 2 are completed successfully, the technology can be rolled out at industrial scale with more features and users. In this phase 3, investment required and adoption complexity is relatively higher because the solution has to be scaled up to support more features and users. Since many of the common failure risks are already addressed in phase 1 and 2, phase 3 i.e. ‘Industrialization’ should target risks related to wider rollout of the use case. The top 3 failure risks are:

- Integration with enterprise software

- Internationalization and data compliance

- Infrastructure availability to support scope and users

What if you do not apply RTF?

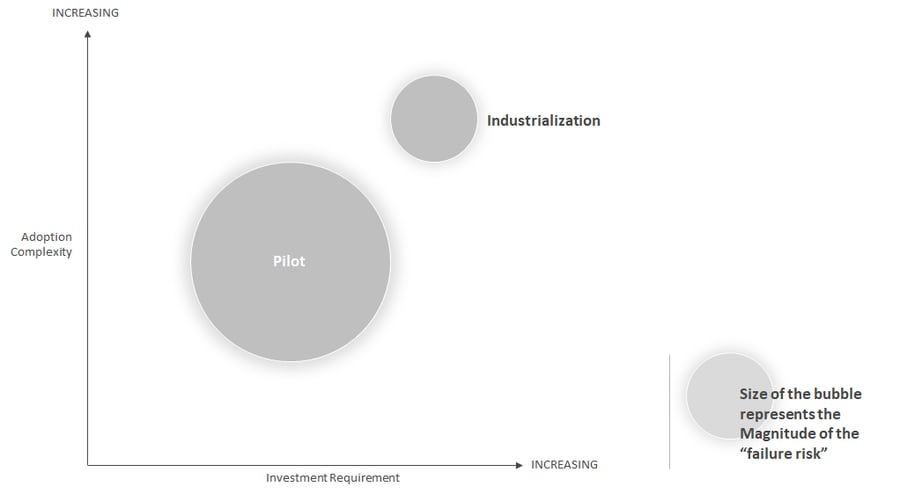

RTF ensures that maximum failure risk is absorbed in initial stages of the project when the investment required and adoption complexity is low. Therefore, if a particular phase is skipped, the risk of that phase gets added to the next phase. This enhanced risk for similar investment requirement and adoption complexity can jeopardizes project outcome (see figure 3).

Figure 3: Failure risks gets added to the next phase in the absence of a phase jeopardizing investment and adoption

Role of Field trials in RTF

Field trial is an important element in the application of RTF as the selected use case for development must demonstrate its value, before it is industrialized, via metrics such as return on investment, error reduction and other key performance indicators. This helps in establishing the role of Assisted Reality technology as a business enabler hence making the field testing process a key pivot point in the adoption of transformative technologies. While each field testing environment is unique, we have created more than 15 best practices for a meticulous field testing process. We describe here 6 of these insights and best practices.

- Reduce organization barriers via senior management sponsorship for the technology solution being implemented. This ensures that the initiative is seen as one of strategic importance and gets organization-wide acceptance.

- Prepare stakeholders for change if the solution being implemented impacts people and essentially changes the way they do business or perform their tasks. The solution will be successful only when the end-user embraces the change. Creating enthusiasm for the technology via voluntary participation and involving them from inception to end are some of the ways that users can be made comfortable with the technology.

- Select the right test conditions as the ecosystem required for field trials should mimic the actual working conditions. Although the MVP in the field trial is often tested with a subset of full-scale operations, we must ensure that the most important users, locations, workflows, data etc. are selected. The importance of these factors can be gauged from their business criticality, failure probability or implementation complexity etc.

- Create a detailed test plan that includes test objectives, test scenarios, stakeholders who will be involved in the tests, especially when the stakeholders are from different teams. This sets the right expectations, smoothens the coordination and keeps the unintended deviations in check.

- Choose and measure the key performance indicators (KPIs) which can determine whether the pilot is successful and ready to be scaled up or the expected outcomes were not realized, and we need to go back to the idea board. These KPIs can be, but not limited to: business benefits, end-user experience, device performance and feasibility of the technology.

- Ensure field agility so that challenges during the field trial can be overcome through adaptation and collaboration. This ensures that field trials can be accomplished within pre-defined timeline and resources.

How Nagarro enables RTF and field trials for Connected Worker 4.0

Industry 4.0 is leading to Smarter Factories and Smarter Services. This technology enhancement creates new challenges for workers. They not only have to be connected but they also need to work across variety of complex assignments. Their role in a Smarter Factory or in offering a Smarter Service increases. Hence, to enable them to succeed – they need new digital tools such as Reality technologies.

Once the right use case of Reality technologies is identified and developed – the use case must be validated for specific objectives through a field trial. Field trials give organizations an opportunity to evaluate technology and its impact while simultaneously limiting escalation of commitment.

In line with Nagarro’s ‘Thinking Breakthroughs’ approach to facilitate innovation and its application for our clients, we offer several toolkit driven approaches – from blue ocean innovation to technology-driven rapid prototypes. Field trials are often an integral part of validating new solutions through these toolkit driven approaches. We work in close collaboration with our clients to create customized and robust field trial plan, identify relevant key performance indicators (KPIs) to measure the success of the field trial and thereafter support execution of field trial.

During the field trial execution, we support our clients to maintain the required test environment, adopt best practices to ensure the accuracy and authenticity of the results and finally our agile approach ensures quick response to manage dynamic situations in field testing. Our extensive experience in implementing RTF increases our customer’s ability to realize business value from usage of Assisted Reality.

.jpg)